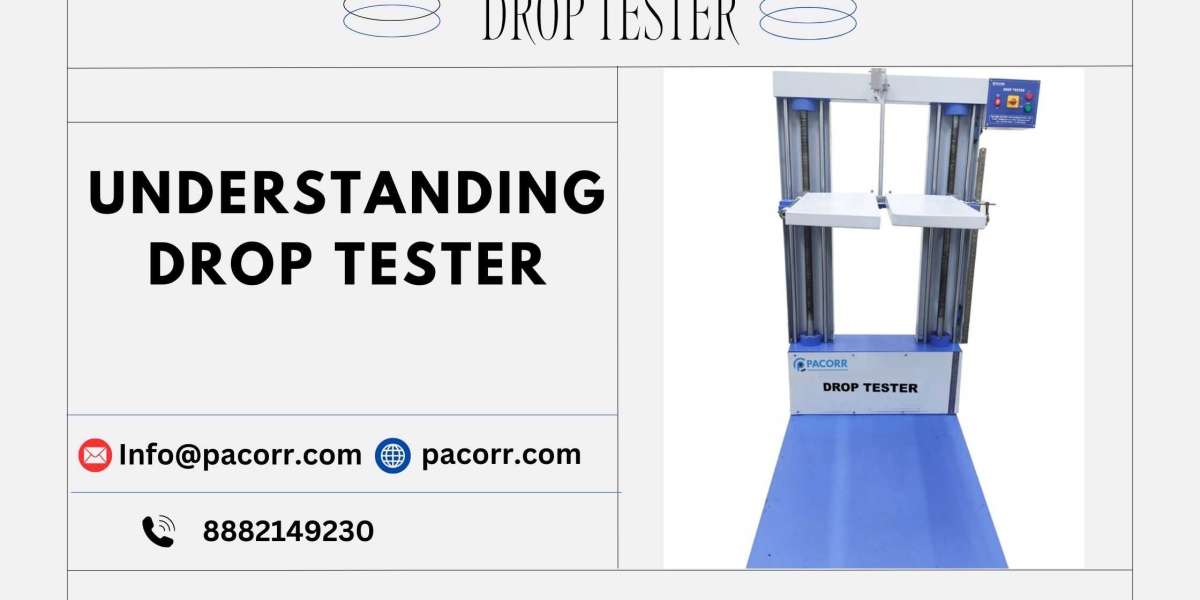

At Pacorr, our Drop Tester is designed to simulate the conditions a package might face during handling, shipping, and storage. This device assesses a product’s ability to withstand impacts, ensuring that it reaches its destination intact and meets quality standards.

What is a Drop Tester?

A Drop Tester is an instrument that measures a product's strength by simulating the drops and impacts it might endure during handling and transit. By dropping the product from a specific height, we can gauge its resilience and identify any potential weaknesses. This Drop Tester Price is particularly relevant for industries dealing with fragile, heavy, or high-value products.

Why Use a Drop Tester?

Using a Drop Tester provides manufacturers with insight into their product's durability. It allows them to:

- Assess Packaging Performance: Ensures the packaging is robust enough to protect the contents.

- Optimize Material Usage: Helps in finding the balance between material cost and packaging strength.

- Enhance Customer Satisfaction: Reduces complaints and returns due to damaged goods.

- Comply with Standards: Many industries have set standards for packaging durability, and drop testing helps meet these.

Key Features of Pacorr’s Drop Tester

The Drop Test Equipment at Pacorr is designed with several advanced features to ensure accurate and reliable testing:

- Adjustable Drop Heights: Allows testing from different heights to meet specific testing requirements.

- Automatic Drop Mechanism: Ensures consistent, controlled drops for reliable results.

- Durable Platform: Provides stability during testing, ensuring the product drops precisely as required.

- Versatile Testing Options: Supports free-fall, corner, edge, and flat drop testing.

Industries Benefiting from Drop Testing

Several industries benefit from using the Drop Tester to secure their products during handling and transit:

- E-commerce: Ensures packages withstand handling and transit challenges.

- Electronics: Protects delicate and high-value items from damage during transportation.

- Pharmaceutical: Ensures medical supplies are delivered safely.

- Automotive and Heavy Machinery: Verifies the strength of packaging for heavy items.

Drop Testing Standards

The Drop Tester helps companies comply with standards, including:

- ASTM D5276: Standard Test Method for Drop Test of Loaded Containers by Free Fall.

- ISTA Standards: International Safe Transit Association (ISTA) standards like 1A and 2A require drop testing to verify package integrity.

- ISO 2248: International standard for the vertical impact test, specifically for packaging.

How to Perform Drop Testing

Using the Drop Tester is straightforward. Here’s a step-by-step guide:

Set the Drop Height: Adjust the Drop Tester Manufacturer to the required drop height.

- Place the Product: Position the package or product on the drop platform.

- Select Drop Orientation: Choose edge, corner, or flat drop, depending on test requirements.

- Initiate the Drop: Use the control mechanism to drop the package.

- Inspect for Damage: Examine the product for any damage to assess packaging integrity.

Benefits of Using Pacorr’s Drop Tester

With Pacorr’s Drop Tester, companies can improve their product quality and meet rigorous industry standards. Key benefits include:

- Improved Durability: By understanding weaknesses, manufacturers can reinforce packaging.

- Cost Savings: Reduces losses due to damages during shipping.

- Customer Trust: Boosts customer confidence by delivering undamaged products.

Why Choose Pacorr’s Drop Tester?

At Pacorr, we focus on quality, precision, and reliability. Our Drop Tester Machine is built with the latest technology and rigorous quality checks, making it the go-to solution for manufacturers looking to safeguard their products. Visit pacorr.com to learn more about the Drop Tester and our other testing solutions tailored to meet your needs.